The 1028155 Idler G-Track is a component designed for use in Caterpillar machinery, particularly in specific models that utilize the G-Track system. Here are the detailed aspects of this idler:

Overview of 1028155 Idler G-Track

- Function:

- The Idler G-Track is responsible for guiding and supporting the tracks of Caterpillar equipment, ensuring smooth operation and maintaining proper tension.

Key Features

- Compatibility:

- Specifically designed to fit various Caterpillar models that utilize G-Track technology.

Specifications

- Weight: Typically weighs around 150-250 pounds (exact weight may vary based on specific applications).

- Material: Constructed from high-strength steel to provide durability and resistance to wear.

- Dimensions: Engineered to fit standard mounting configurations for easy installation.

Additional Information

- Installation:

- Designed for easy installation, commonly requiring standard tools for setup.

- Performance:

- Vital for maintaining track alignment and tension, contributing to the overall performance and efficiency of the machinery.

Application

- Designed for use in various Caterpillar tracked machines to support the undercarriage and maintain proper track tension.

Specifications

- Construction: Made from high-strength steel for durability and longevity under heavy loads.

- Design: Engineered to provide effective track alignment and support.

- Bearings: Typically includes sealed bearings to minimize friction and enhance service life.

- Dimensions: Specific dimensions may vary; refer to Caterpillar specifications for exact measurements.

Importance

The idler group is crucial for maintaining the efficiency and stability of the track system, helping to ensure smooth operation and prolonging the life of the tracks. Regular inspection and timely replacement of worn idlers are vital for optimal performance.

If you have further questions about the 1028155 Idler G-Track or need additional details, feel free to ask!

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.

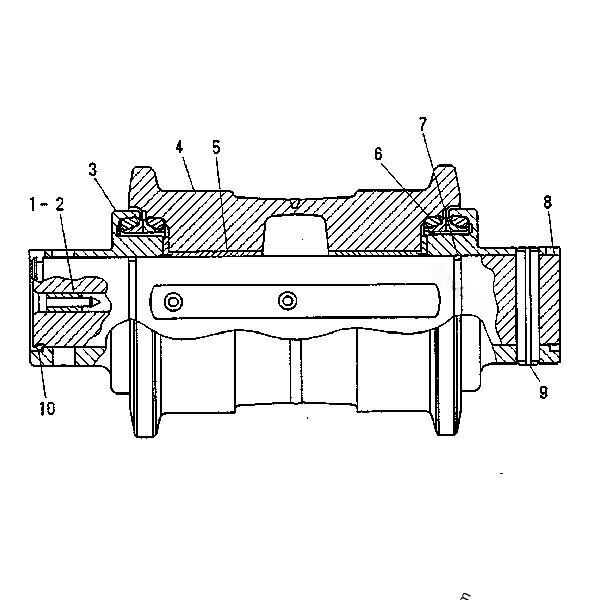

Track roller diagram

| NOTE | No. | PART No. | QTY | PART NAME |

| 1 | 6Y-6201 | 1 | RIXG | |

| 2 | 5G-2247 | 1 | STOPPER | |

| 3 | 6Y-0473 | 1 | PLUG | |

| 4 | 6Y-1054 | 2 | COLLAR | |

| 5 | 6I-9398 | 1 | ROLLER AS | |

| 6 | 6I-9399 | 2 | BEARING | |

| 7 | 1H-8720 | 2 | SEAL | |

| 8 | 6I-9397 | 1 | SHAFT | |

| 9 | 9W-2204 | 1 | PIN | |

| 10 | 9W-7225 | 2 | SEAL GP |