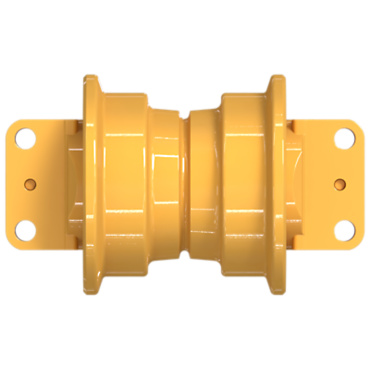

383-6965 – CAT Bottom / Track Roller

Home » Excavator undercarriage parts »The 383-6965 CAT Track Roller is a vital component in the undercarriage of Caterpillar machinery, designed to support and enhance the performance of tracked vehicles. Below is a detailed overview of its features, functionality, and advantages.

- Part Number: 383-6965

- Description: Bottom Roller / Track Roller

- Application:

- The 383-6965 bottom/track roller is used on various Caterpillar crawler-type machines, including:

- Caterpillar D3, D4, D5, and D6 series crawler tractors

- Caterpillar 311, 312, 315, and 319 series excavators

- The 383-6965 bottom/track roller is used on various Caterpillar crawler-type machines, including:

- Function:

- The bottom/track roller is a component within the undercarriage of tracked Caterpillar equipment.

- It helps support the weight of the machine and guides the track as it travels around the track frame.

- The roller reduces friction and wear on the track, contributing to smoother and more efficient operation.

- Replacement and Maintenance:

- Bottom/track rollers like the 383-6965 are subject to wear during normal use and may need to be inspected and replaced periodically.

- Consult the specific Caterpillar service manual for your equipment model to get the proper procedures for inspecting, adjusting, and replacing the 383-6965 bottom/track roller.

- Proper maintenance and timely replacement of these rollers is important to maintain the performance and lifespan of the tracked undercarriage system.

Key Features of the 383-6965 Track Roller

- Compatibility: Specifically designed for certain models of Caterpillar equipment, ensuring a precise fit.

- Durable Construction: Manufactured from high-quality materials to withstand the rigors of heavy-duty applications.

- Dimensions: Tailored to meet the specific size and design requirements for effective installation.

- Weight: Balances strength and manageability for easier handling during installation and maintenance.

Functionality

The 383-6965 Track Roller serves several important functions:

- Track Support: Provides essential support for the tracks, facilitating smooth movement across various terrains.

- Weight Distribution: Helps in evenly distributing the weight of the machinery, which minimizes wear on other undercarriage components.

- Friction Reduction: Reduces friction between the track and ground, enhancing overall operational efficiency.

Advantages of Using the 383-6965 Track Roller

- Enhanced Performance: Improves the performance of Caterpillar machinery by ensuring proper track alignment and stability.

- Durability: Designed for longevity, the roller reduces the need for frequent replacements, saving on maintenance costs.

- Cost Efficiency: Decreases downtime and maintenance requirements, providing a better return on investment for operators.

Maintenance Recommendations

To ensure the longevity and optimal performance of the 383-6965 CAT Track Roller, consider the following maintenance practices:

- Regular Inspections: Frequently check for signs of wear, damage, or misalignment.

- Adequate Lubrication: Ensure proper lubrication to minimize friction and prolong the life of the roller.

- Track Condition Monitoring: Regularly monitor the condition of the tracks to prevent excessive wear on the roller.

- Debris Removal: Keep the area around the roller clean to avoid debris accumulation that could impair functionality.

Conclusion

The 383-6965 CAT Track Roller is an essential component for the effective operation of Caterpillar machinery. Understanding its features, advantages, and necessary maintenance practices will help operators maximize efficiency and extend the lifespan of their equipment. If you have any further questions or require additional information, feel free to ask!