Keywords: excavator buckets, excavator grading bucket, excavator skeleton bucket

excavator buckets

excavator grading bucket

excavator skeleton bucket

Finding the right kind of excavator for a job is one thing, but finding the right excavator bucket for your project can make or break your efficiency. When it comes to the different types of excavator buckets, you can find finishing, digging and trenching buckets — each equipped to carry out a specific task. With 11 excavator buckets to choose from, it can be difficult to tell which one will fit your needs best, especially when some buckets have overlapping characteristics. If you’re having trouble making a decision, you’re in the right place. In this article, we’re breaking down each excavator bucket in detail and answering some of the most common questions people have about excavator attachments.

- 1. Digging Bucket

- 2. Rock Bucket

- 3. Utility Bucket

- 4. Grading Bucket

- 5. Tilt Ditch Cleaning Bucket

- 6. V Bucket

- 7. Frost Bucket

- 8. Micro Trenching Bucket

- 9. Skeleton Bucket

- 10. Rake Riddle Bucket

- 11. Clean-up Bucket

- Excavator Bucket FAQ

- Rent Your Excavator and Heavy Machinery

1. Digging Bucket

The digging bucket is likely what one envisions when they’re thinking of a traditional bucket on an excavator. The digging bucket has multiple uses, but its main use is right in the name — digging!

A digging bucket typically features teeth on the end of the bucket that allow it to break through and dig up hard surfaces for general construction and landscaping purposes. While the digging bucket is the most popular, it’s not always the best choice. Projects that require digging up a hard surface may benefit from using a rock or frost bucket (more on those later), and then using a digging bucket to finish the job.

Best for: Digging up hard surfaces and moving material in general construction and landscaping projects.

2. Rock Bucket

A rock bucket is ideal for compact and hard surfaces that you need to break through. A rock bucket is reinforced for extra strength that can withstand a lot of pressure, but the most notable feature of a rock bucket is its sharp teeth that can better penetrate stubborn surfaces when a digging bucket just won’t do.

A rock bucket is an extremely versatile option, as you can use it for various projects where digging and moving materials are necessary. Asphalt removal and stone extraction are two projects where you’d often see a rock bucket.

Best for: Penetrating and breaking up solid surfaces like asphalt, stone and large sheets of rock.

3. Utility Bucket

Utility buckets prove to be extremely useful when you’re excavating near pipes and cables. Cable strikes are inconvenient and can harm to the excavation crew. With the utility bucket, construction crews can continue their digging or trenching without running the risk of striking a utility line.

Instead of teeth at the edge of the bucket, a utility bucket uses a rounded edge that is double-enforced for structural integrity. This rounded edge keeps excavators from accidentally catching loose cables and wires. Utility buckets are often seen on a project in a residential area that uses underground systems for their water, gas, electricity and other utilities.

Best for: Digging near utility lines and pipes without running the risk of striking a cable.

4. Grading Bucket

A grading bucket is another common excavator bucket, but instead of using it for digging, a contractor uses it for smoothing and leveling a surface. Grading buckets, also known as finishing or trench cleaning buckets, are short, shallow and wide.

Grading buckets are not designed to move heavy materials but instead create a flat profile at the end of a project. The excavator operator achieves a smooth surface by dragging the long, flat edge of the bucket along the ground to distribute a fine aggregate. The nickname “finishing bucket” refers to when a project is over a contractor would use a grading bucket to clean up and level everything back out.

Best for: Leveling and profiling the ground to leave a smooth finish, also known as grading. Works best with softer materials such as fine dirt and sand.

5. Tilt Ditch Cleaning Bucket

A tilt ditch cleaning bucket is true to its name. It’s a cleaning bucket with a similar build to a grading bucket. What makes this bucket special is that it can tilt 45 degrees left or right, allowing the operator to work at an angle.

A contractor typically uses a tilt ditch cleaning bucket when working on a trench or a sloping surface. Many consider this bucket to be a “finishing” bucket, so it’s typical to use it at the end of the project to tidy things up and leave a smooth finish.

The tilt ditch cleaning bucket is similar to the grading bucket because it uses a flat and wide edge to distribute and smooth out soil, sand or fine dirt.

Best for: Smoothing, cleaning and finishing more complex projects set on a slope or an otherwise uneven surface.

6. V Bucket

There’s nothing quite like the V bucket. Its unique shape creates clean v-shaped trenches with a swoop of the excavator’s arm. Depending on the material you’re trenching, a V bucket could come with or without teeth, but a more compact surface would require teeth to assist with the digging portion of the task.

A V bucket is useful for various projects, but they are most useful for creating narrow trenches where someone could lay cables and pipes. V-shaped trenches are also useful for creating a ditch that offers drainage. While the bucket does not look overly large, it is a complex attachment that needs a decent amount of power to drive it. For this reason, V buckets are best paired with a larger excavator.

Best for: Digging and cleaning v-shaped trenches where you will lay pipes and cable.

7. Frost Bucket

You might think of a frost bucket as the rock bucket’s more advanced brother. A frost bucket is equipped with additional teeth on the backside of the bucket. Frost buckets rip through hard surfaces easier than any other bucket due to their specific design that can dig through the frozen ground.

Depending on the project’s climate, a rock bucket might not be the right solution for excavating. In mountainous and extremely cold environments, it’s common for the ground to freeze during the winter, making an already hard surface even harder. Thanks to its extra teeth, a frost bucket can rip through the ice, rocks, compact dirt and virtually any sediment.

Best for: Breaking up extremely compact and hard surfaces — especially those where rock buckets can’t quite dig through.

8. Micro Trenching Bucket

A micro trenching bucket is a narrow, almost claw-like bucket that creates trenches that are only a few inches wide yet considerably deep. Since the bucket digs much smaller trenches, it can save contractors a significant amount of time in digging and backfilling.

A micro trenching bucket may also be known as a fiber-optic bucket because its creation was intended for creating small trenches that fiber-optic cables could run through. While the micro trenching bucket is still in use for this purpose today, it’s also useful for laying pipes and irrigation systems.

Best for: Digging narrow trenches that are only a few inches wide that are useful for laying cables, pipes and irrigation systems.

9. Skeleton Bucket

At first glance, a skeleton bucket looks a lot like a digging bucket, but there’s one key difference that sets the two apart. The back of a skeleton bucket has large slots or a grid that allows fine materials to pass through, therefore sifting out the larger materials.

A skeleton bucket is useful for doing two jobs at once. It can dig up large amounts of material while separating large pieces of stone, trash, concrete and other materials. The benefit of separating the finer materials from the larger ones is reusing the sediment to backfill trenches and ditches or recycle it for another project.

Best for: Separating aggregates like large rocks or other materials from dirt. Often used in projects where you will separate dirt, soil and sand and reuse them in other aspects of the project.

10. Rake Riddle Bucket

Rake riddle buckets are similar to a skeleton bucket since the two buckets feature slats for debris to fall through. However, rake riddle buckets serve a slightly different purpose. The word “rake” is essential to the bucket’s name because that’s exactly what it does.

While other buckets are deeper with a larger carrying capacity, this bucket focuses more on using its long teeth to effectively rake through dirt and soil. Rake riddles are useful for the sole purpose of separating aggregate and trash from a load. You will most commonly use them for loosening and digging up tree roots, shrubs and grass while saving the soil for later use.

Best for: Digging out tree roots and shrubbery while allowing soil, dirt and other fine aggregates to pass through.

11. Clean-up Bucket

Clean-up buckets are another type of finishing bucket that is equipped with a straight edge and long width for grading and smoothing out the surface. However, clean-up buckets have a larger carrying capacity than other finishing buckets, in fact, it’s almost similar to that of a digging bucket.

While a clean-up bucket is definitely not meant for digging, its larger capacity proves helpful when a worksite needs cleaning. The clean-up bucket can carry and remove large loads of loose materials, leaving a worksite better than it was found.

A clean-up bucket is essentially an all-in-one finishing bucket that can level a surface and haul away large loads. If you’re in need of a grading bucket, this bucket can check off two needs at once.

Best for: Cleaning up a job site and shoveling loose materials. You can also use it for grading and smoothing materials for a finished appearance.

Excavator Bucket FAQ

With so many types of excavator buckets, it can be easy to feel overwhelmed by the options and models. Here are some of the most commonly asked questions about excavator buckets and their answers.

What Are Common Excavator Bucket Sizes?

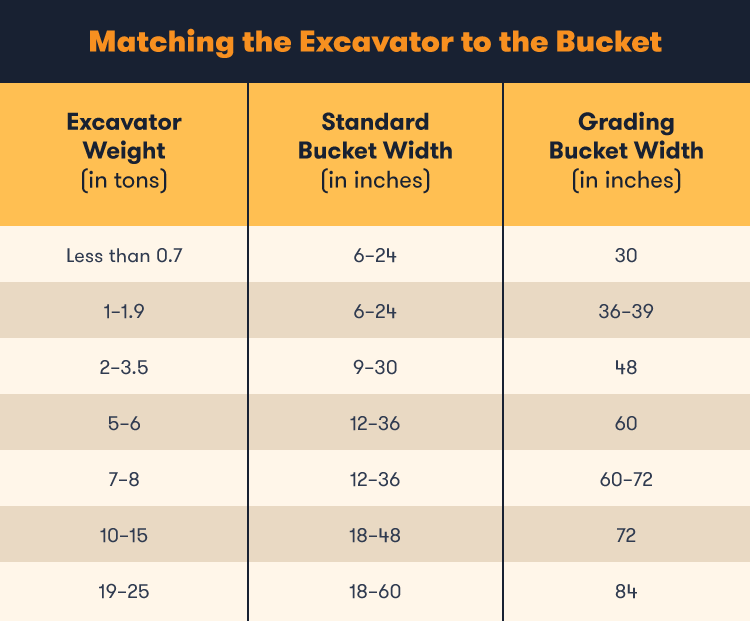

Excavator bucket sizes are always measured by their inside width. As a rule of thumb, the larger the excavator, the larger bucket it can handle.

Mini excavator bucket sizes typically range from six-inch specialty buckets up to 30-inch grading buckets. While the largest of excavators can handle up to an 84-inch grading bucket. This chart can be a helpful reference for what size bucket will match the size of the excavator you use:

Are Excavator Buckets Universal?

Unfortunately, bucket sizes are not universal. Choosing the right excavator bucket is completely dependent on the machine with which you work. While some excavator buckets may fit a range of machines, it’s not standard to use a bucket that is not specifically designed to fit the excavator.

Key takeaway: Always account for the make, model and size of your machine before purchasing or renting an excavator bucket.

What Are the Different Types of Excavator Buckets?

Excavator buckets come in different shapes and sizes, all with unique functions. If you’re not sure which bucket to choose for your excavation project, here are the 11 types of excavator buckets and their uses:

- Digging bucket: A common bucket type that serves to dig and move material in general construction and landscaping projects.

- Rock bucket: A specialty bucket designed with additional durable teeth that can break up hard, compact surfaces.

- Utility bucket: This specialty bucket is designed to avoid utility piping and cables while digging.

- Grading bucket: Grading buckets are designed for smoothing and finishing softer materials to create a level surface.

- Tilit ditch cleaning bucket: This is a smoothing and finishing bucket that can be angled for use on a slope.

- V bucket: V buckets create a v-shaped trench you will use to prepare for laying piping and utility cables.

- Frost bucket: This is the more advanced version of a rock bucket you will use to break up extremely compact surfaces.

- Micro trenching bucket: A micro trenching bucket is a narrow, claw-like tool that creates trenches only a few inches wide that are suitable for cables and irrigation.

- Skeleton bucket: This bucket sifts through materials and separates larger aggregate from dirt and soil.

- Rake riddle bucket: Rake riddle buckets dig roots and landscaping out of the ground while allowing fine aggregate to pass through.

- Clean-up bucket: This is a finishing bucket that picks up and moves loose materials.

How Do I Choose an Excavator Bucket?

When choosing the right excavation bucket, you’ll have to consider various factors. From worksite conditions to potential hazards, here’s everything you need to consider before deciding on the right excavator bucket:

- Worksite conditions: What is the size of your workspace? Are you in a wide, open area where you can use a large excavator and bucket? Or in a smaller, compact area where you can only fit a mini-excavator with a smaller bucket?

- Climate: Climate can have a big impact on your work site. For example, cold and dry climates may require the extra force of a rock or frost bucket if the ground is frozen, whereas humid climates often have softer soil that may not require as much digging power.

- Ground conditions: How compact is the ground? If you’re trying to dig up extremely compact surfaces, you may require a rock or frost bucket to break up the material first.

- Surrounding hazards: Are there any potential hazards to be aware of? Are you digging near utility cables or irrigation systems? If so, you may consider a utility bucket.

- Job description: Excavators can serve in many different capacities. Are you trenching, digging, breaking up material or finishing? Do you need to sift through any aggregate? Consider the purpose of the project while shopping around for the right bucket.

Rent Your Excavator and Heavy Machinery

Now that you’re all caught up on the different types of excavator buckets, you can choose the right bucket and excavator for the job. No matter the excavator, remember that the bucket type is just as important as the excavator itself.

When it comes to excavators, BigRentz has top-of-the-line excavators of all sizes available to rent across the United States. So, when you’re in need of an excavator for a job, BigRentz has you covered.