Keywords: excavator compaction wheel, compaction wheel for excavator, mini excavator compaction wheel, compaction wheel excavator, compaction wheel for mini excavator, compaction wheel for mini excavators

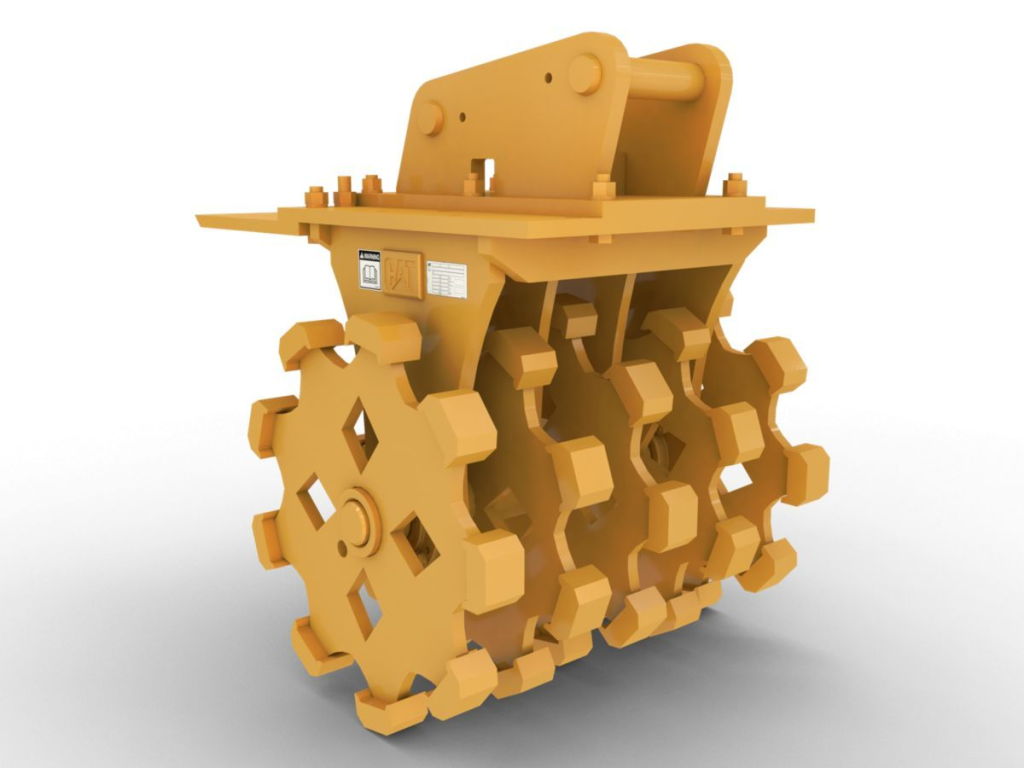

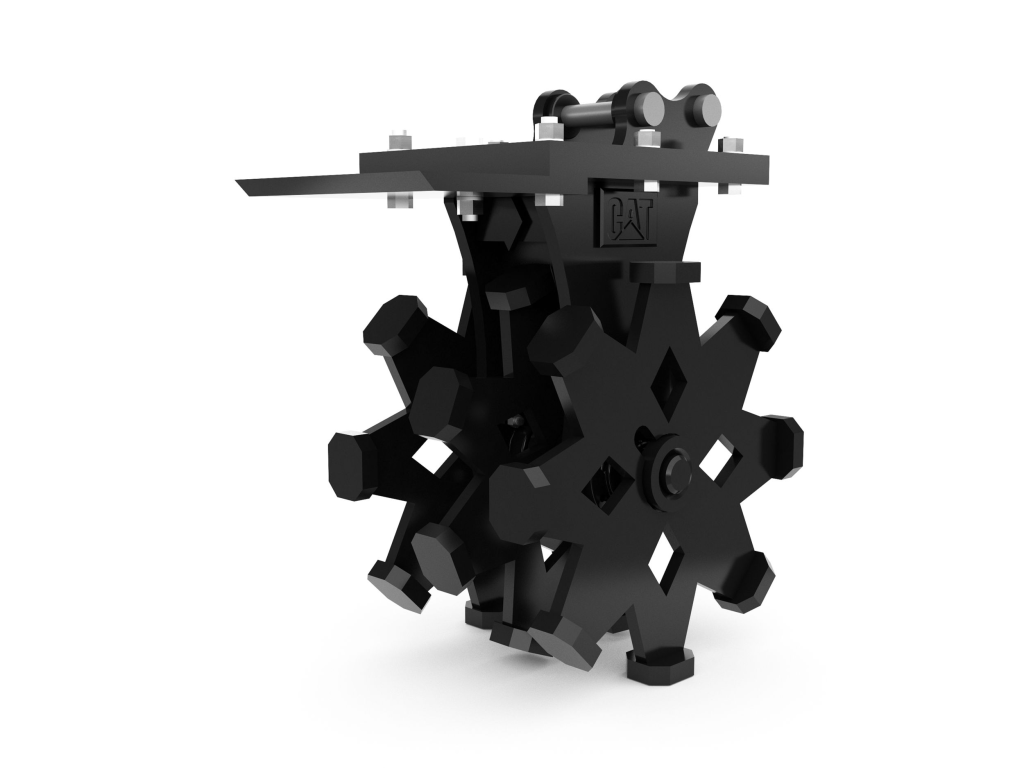

Excavator compaction wheel

Compaction wheel for mini excavator

In the world of construction and earthmoving equipment, mini excavators have carved out a unique niche for themselves. These compact, maneuverable machines excel at tasks that require precision, tight spaces, and adaptability. And for mini excavator owners looking to expand the capabilities of their equipment, one attachment stands out as a game-changer – the compaction wheel.

Compaction Wheels: The Mini Excavator’s Versatile Sidekick

Compaction wheels are specialized attachments that mount directly to the undercarriage or rear of a mini excavator. These wheel-based systems are designed to apply high levels of compaction force to soil, gravel, and other materials, making them an essential tool for a wide range of site preparation and landscaping tasks.

Unlike the traditional drum-style compactors, mini excavator compaction wheels offer several key advantages:

- Compact and Maneuverable: The small footprint of a compaction wheel allows it to easily access tight spaces and work in confined areas where larger equipment cannot reach.

- Precise Control: By integrating the compaction system with the mini excavator’s advanced hydraulic controls, operators can precisely regulate the speed, force, and coverage of the compaction process.

- Increased Productivity: The ability to compact materials while moving the excavator allows for faster, more efficient site preparation compared to traditional methods.

- Versatility: Compaction wheels can handle a wide range of soil types, gravel, and other materials, making them a valuable tool for landscaping, utility work, road construction, and more.

Applications of Mini Excavator Compaction Wheels

The versatility of compaction wheels makes them a valuable addition to any mini excavator fleet, with applications spanning numerous construction and landscaping disciplines:

Site Preparation: Compact soil, gravel, and other materials to create a stable, level foundation for new construction projects.

Utility Installation: Compact backfill around buried pipes, cables, and other underground utilities to prevent settling and ensure long-term integrity.

Landscaping: Compact soil and aggregate for patios, walkways, and other hardscaping elements, ensuring a stable, durable finish.

Road and Parking Lot Construction: Compact sub-base and surface materials to create a solid, long-lasting pavement structure.

Trench Compaction: Compact backfill in narrow trenches for utilities, drainage systems, and other linear infrastructure.

By equipping their mini excavators with compaction wheel attachments, contractors and landscapers can significantly improve the efficiency, quality, and versatility of their earthmoving operations. This powerful combination of compact size, precise control, and high-performance compaction capability makes the mini excavator-compaction wheel setup an invaluable asset on any job site.

As the construction industry continues to demand more from its equipment, innovative attachments like the compaction wheel will undoubtedly play an increasingly crucial role in the future of mini excavator applications. By expanding the capabilities of these nimble and adaptable machines, contractors can tackle an ever-wider range of projects with confidence and efficiency.