hydraulic breaker for mini excavator

Definition and function

Hydraulic breaker is a device installed on construction machinery such as excavators and used to break hard objects such as rocks and concrete. For mini excavators, the hydraulic breaker also plays this role, but due to the size and power limitations of the mini excavator, the hydraulic breaker also needs to be adapted and adjusted accordingly.

Types and Classifications

Hydraulic breakers

Operation Methods: Handheld and machine-mounted types. For mini excavators, the machine-mounted type is typically used.

Working Principles: Fully hydraulic, hydro-pneumatic, and nitrogen explosion. Most breakers on the market today are hydro-pneumatic, relying on both hydraulic oil and compressed nitrogen to drive the piston.

Valve Structures: Internal valve and external valve configurations.

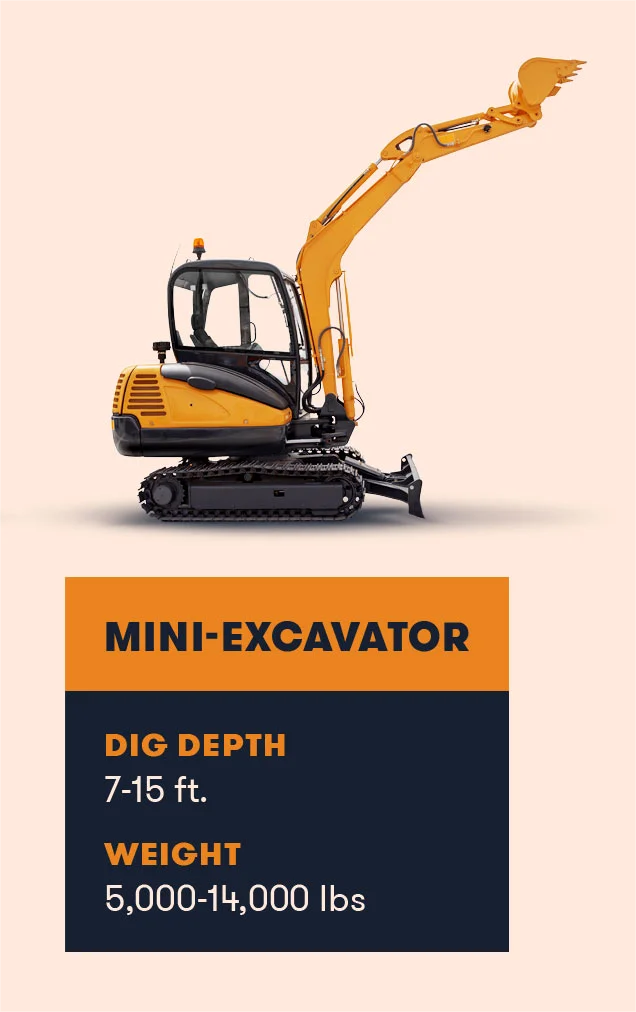

Mini excavators are a compact version of an excavator, occasionally small enough to fit through a doorway. Their petite size and versatility make them one of the easiest pieces of excavating machinery to use. Whether you’re digging a hole in your backyard or removing debris from a small demolition, mini excavators can do it all with minimal tracking, noise and hassle.

If you’re interested in renting a mini excavator, it’s important to understand how it differs from its parent machine, the excavator. An excavator weighs around 68,000 pounds and can move nearly five times the weight of a mini excavator. Therefore, a mini excavator is best suited for smaller-sized projects.

What can a mini excavator do?

Don’t let the size of a mini excavator fool you — they can do more than you’d expect. These machines are perfect for small and tight construction sites where bigger machines like tractors or excavators won’t fit. Owning or renting a mini excavator can help you with a variety of projects such as:

Mini Excavator Size

Mini excavators, with their small size and light weight (typically between 1 and 8 tons, approximately 5,000-14,000 pounds), are a flexible complement to standard full-size excavators. They can easily maneuver through narrow spaces, such as urban alleys, inside buildings, or areas that are difficult to reach for large machinery, demonstrating excellent mobility and adaptability.

Mini excavators are ideal for projects that require efficient work in limited spaces. Not only can they operate flexibly in a closed environment, they can also enter corners that cannot be reached by large equipment to complete various tasks such as excavation and loading. In addition, its lightweight body is also easy to transport and install, allowing it to quickly respond to various construction needs.

So, if you’re looking for an excavating device that can easily maneuver through tight spaces and handle a variety of construction challenges, a mini excavator is the perfect choice for you.

Mini Excavator Rotation

One of the major benefits of a mini excavator is its rotation range of 360 degrees, a complete circle. An operator can use the functions of a mini excavator’s front arm in front, to the sides and behind the operator’s cab.

What size is the smallest mini excavator?

However, there are often considered to be three sizes of mini excavator models: small, medium, and large. Small mini excavators have operating weights ranging from 2,000 to 10,000 pounds, medium excavators range between 10,000 and 18,000 pounds, and large mini excavators exceed 18,000 pounds.