The 270-00048 Track Roller is a vital component used in various heavy machinery, particularly in the undercarriage systems of excavators and other tracked vehicles. This guide will cover its features, benefits, applications, and maintenance tips.

Key Features

1. Durable Construction

- High-Strength Materials: Made from premium steel for enhanced durability and resistance to wear and tear.

- OEM Standards: Manufactured to meet or exceed Original Equipment Manufacturer (OEM) specifications, ensuring compatibility and reliability.

The 270-00048 rollers are commonly used in several excavator models, particularly from the Caterpillar and Doosan brands. Here are some excavator models that are compatible with the 270-00048 rollers:

Caterpillar Models

- Caterpillar 320

- Caterpillar 325

- Caterpillar 330

- Caterpillar 336

Doosan Models

- Doosan DX225LC

- Doosan DX300LC

- Doosan DX340LC

Additional Notes

- Compatibility may vary based on the specific machine configuration and manufacturing year.

- It is always recommended to check the service manual or consult with the manufacturer to ensure the correct fit for your specific excavator model.

2. Design Specifications

- Roller Diameter: Typically designed to fit specific models, check the dimensions to ensure proper fit.

- Weight Capacity: Engineered to support significant weight, contributing to the stability of the machinery.

Benefits

1. Enhanced Performance

- Smooth Movement: Provides smooth operation of the track system, which is crucial for efficient machine performance.

- Improved Traction: A well-functioning track roller enhances the overall traction of the machinery, making it more effective on various terrains.

2. Cost-Effectiveness

- Reduced Downtime: Reliable performance minimizes equipment failures, leading to less downtime and increased productivity.

- Long Lifespan: High-quality materials and construction result in a longer operational life, reducing the frequency of replacements.

3. Versatile Applications

- Common Uses: Suitable for various applications, including:

- Construction Projects

- Mining Operations

- Site Preparation

- Landscaping

Maintenance Tips

1. Regular Inspections

- Check for Wear: Regularly inspect the track roller for signs of wear, cracks, or misalignment to prevent further damage.

2. Proper Lubrication

- Maintain Lubrication: Ensure that the roller is adequately lubricated to reduce friction and wear over time.

3. Monitor Track Tension

- Adjust Tension: Regularly check and adjust the track tension to ensure optimal performance and prevent undue stress on the roller.

4. Keep the Area Clean

- Remove Debris: Keep the roller area free from dirt and debris that could affect its functionality.

5. Professional Servicing

- Consult Experts: If you notice persistent issues, consider consulting with a professional for a thorough inspection and service.

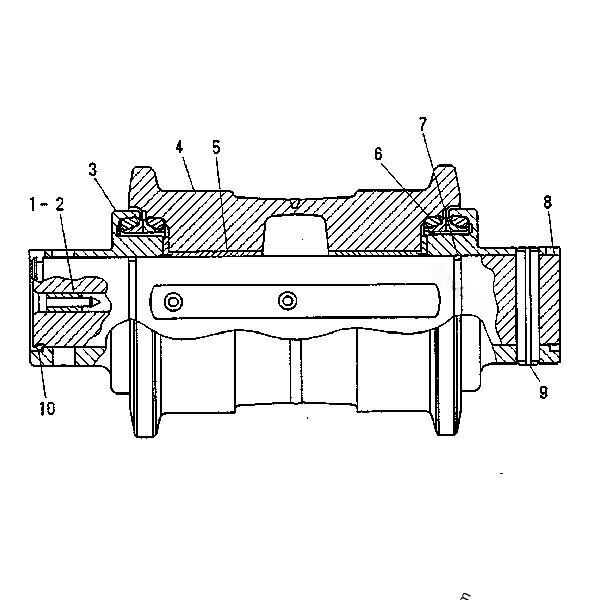

Track roller diagram

| NOTE | No. | PART No. | QTY | PART NAME |

| 1 | 6Y-6201 | 1 | RIXG | |

| 2 | 5G-2247 | 1 | STOPPER | |

| 3 | 6Y-0473 | 1 | PLUG | |

| 4 | 6Y-1054 | 2 | COLLAR | |

| 5 | 6I-9398 | 1 | ROLLER AS | |

| 6 | 6I-9399 | 2 | BEARING | |

| 7 | 1H-8720 | 2 | SEAL | |

| 8 | 6I-9397 | 1 | SHAFT | |

| 9 | 9W-2204 | 1 | PIN | |

| 10 | 9W-7225 | 2 | SEAL GP |

Conclusion

The 270-00048 Track Roller is an essential part of heavy machinery, contributing to its overall performance and efficiency. Understanding its features, benefits, and maintenance practices can help ensure that your equipment operates smoothly and effectively. If you have any further questions or need assistance, feel free to ask!