The 270-00053A track roller is an essential component used in various excavators, providing support and stability for the track system. Here are the key details regarding the 270-00053A track roller:

Overview of 270-00053A Track Roller

- Purpose: Supports the weight of the excavator and ensures smooth movement of the tracks during operation.

- Durability: Designed to withstand harsh operating conditions and heavy loads.

Compatible Excavator Models

The 270-00053A track roller is commonly compatible with the following excavator models:

- Caterpillar 320C

- Caterpillar 320D

- Caterpillar 325C

- Caterpillar 325D

- Caterpillar 330C

Key Features

- Robust Construction: Built to endure demanding environments, enhancing the longevity of the roller.

- Performance Improvement: Aids in maintaining smooth and efficient track movement, which is vital for excavation tasks.

- Simple Installation: Designed for compatibility with specific models for easy installation and replacement.

Application

- Designed for use in various tracked equipment, such as excavators and bulldozers, to support the undercarriage and maintain proper track alignment.

Specifications

- Construction: Made from high-strength steel for durability in demanding conditions.

- Design: Usually features a single flange to effectively guide the track.

- Bearings: Often includes sealed bearings to reduce friction and enhance service life.

- Dimensions: Specific dimensions may vary; it’s best to refer to the manufacturer’s specifications for precise measurements.

Importance

Track rollers are essential for the proper functioning of the track system, ensuring stability and minimizing wear on the tracks and other components. Regular inspections and timely replacements are critical for optimal performance.

Maintenance Tips

- Regular Inspections: Periodically check the track roller for wear or damage to ensure it is functioning properly.

- Proper Lubrication: Ensure the track roller is adequately lubricated to prevent overheating and wear.

- Timely Replacement: Replace the roller when significant wear is detected to maintain optimal excavator performance.

If you have any additional questions or need further assistance regarding the 270-00053A track roller, feel free to ask!

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.

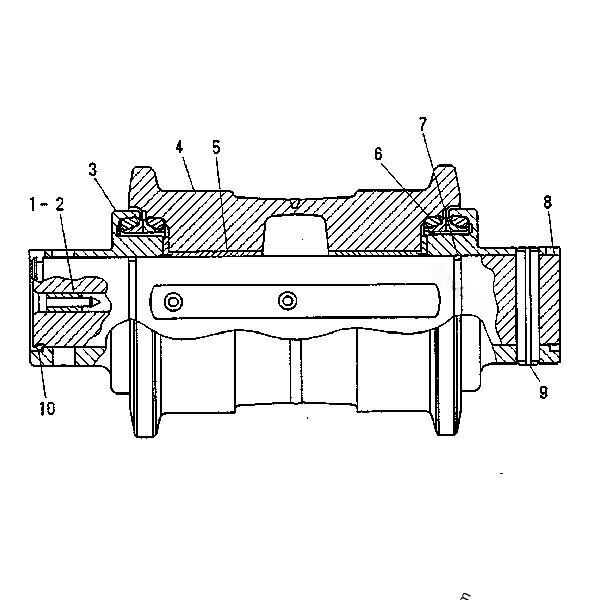

Track roller diagram

| NOTE | No. | PART No. | QTY | PART NAME |

| 1 | 6Y-6201 | 1 | RIXG | |

| 2 | 5G-2247 | 1 | STOPPER | |

| 3 | 6Y-0473 | 1 | PLUG | |

| 4 | 6Y-1054 | 2 | COLLAR | |

| 5 | 6I-9398 | 1 | ROLLER AS | |

| 6 | 6I-9399 | 2 | BEARING | |

| 7 | 1H-8720 | 2 | SEAL | |

| 8 | 6I-9397 | 1 | SHAFT | |

| 9 | 9W-2204 | 1 | PIN | |

| 10 | 9W-7225 | 2 | SEAL GP |