Overview of Caterpillar 325 Excavator

The Caterpillar 325 excavator is a robust and efficient machine designed for various heavy-duty applications in construction, excavation, and demolition. It combines power, versatility, and advanced technology to meet the demands of modern job sites.

Key Features

- Engine Performance:

- Powered by a Cat C7.1 engine, delivering strong performance and fuel efficiency while complying with emission regulations.

- Operating Weight:

- Typically ranges from 25,000 to 30,000 pounds, depending on the configuration and attachments.

- Hydraulic System:

- Features a high-performance hydraulic system for excellent lifting capacity and digging force, enabling precise control.

- Digging Depth:

- Maximum digging depth of approximately 16 feet, suitable for a variety of excavation tasks.

- Reach:

- Maximum reach at ground level is around 24 feet, allowing for effective material handling and operation in tight spaces.

Specifications Table

- Construction: Ideal for site development, grading, and material handling tasks.

- Excavation: Efficient for trenching, digging foundations, and earthmoving operations.

- Demolition: Suitable for breaking down structures and clearing debris.

Applications

| Specification | Details |

|---|---|

| Engine Model | Cat C7.1 |

| Operating Weight | 25,000 – 30,000 lbs |

| Max Digging Depth | Up to 16 feet |

| Max Reach | Up to 24 feet |

| Bucket Capacity | Varies (typically 0.4 – 1.2 m³) |

| Travel Speed | Approximately 3.5 mph |

Maintenance Tips

If you have any specific questions about the Caterpillar 325 Excavator or need more information, feel free to ask!

- Regularly check and change hydraulic fluid and filters.

- Inspect the undercarriage and tracks for wear.

- Schedule routine engine maintenance to ensure longevity and performance.

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.

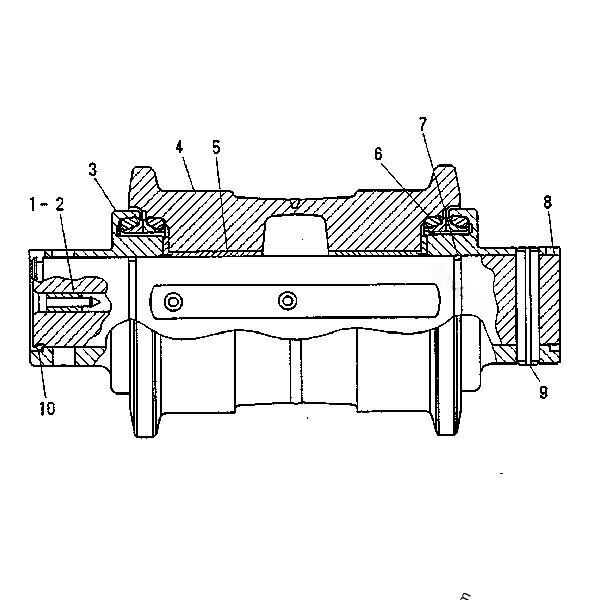

Track roller diagram

| NOTE | No. | PART No. | QTY | PART NAME |

| 1 | 6Y-6201 | 1 | RIXG | |

| 2 | 5G-2247 | 1 | STOPPER | |

| 3 | 6Y-0473 | 1 | PLUG | |

| 4 | 6Y-1054 | 2 | COLLAR | |

| 5 | 6I-9398 | 1 | ROLLER AS | |

| 6 | 6I-9399 | 2 | BEARING | |

| 7 | 1H-8720 | 2 | SEAL | |

| 8 | 6I-9397 | 1 | SHAFT | |

| 9 | 9W-2204 | 1 | PIN | |

| 10 | 9W-7225 | 2 | SEAL GP |