mini excavator bucket types

Mini Excavator Buckets

When it comes to mini excavators, the bucket you choose can make a big difference in your machine’s performance and productivity. From standard digging buckets to specialized attachments, there’s a wide range of bucket options to consider for your mini ex.

Selecting the ideal bucket for your mini excavator and project needs requires understanding the different bucket types and their applications. Let’s take a closer look at some of the key factors to keep in mind.

Standard Digging Buckets

The most common and versatile bucket for a mini excavator is the standard digging bucket. These buckets are designed for general excavation, trenching, and material handling tasks.

Key features of standard digging buckets include:

- Curved shape for efficient scooping and loading

- Serrated or smooth cutting edge for penetrating hard surfaces

- Side cutters to prevent material from spilling out

- Width ranging from 24 to 48 inches, to match your mini ex’s size

For many mini excavator applications, the standard digging bucket is a reliable all-purpose choice.

Specialty Mini Excavator Buckets

In addition to the standard digging bucket, mini excavator operators have access to a variety of specialty bucket attachments, each optimized for specific tasks:

- Grading Buckets – Featuring a flatter profile, grading buckets are ideal for finish grading, site leveling, and backfilling.

- Ditch Cleaning Buckets – With a narrow, elongated shape, ditch cleaning buckets can reach into tight spaces to clear drainage ditches and channels.

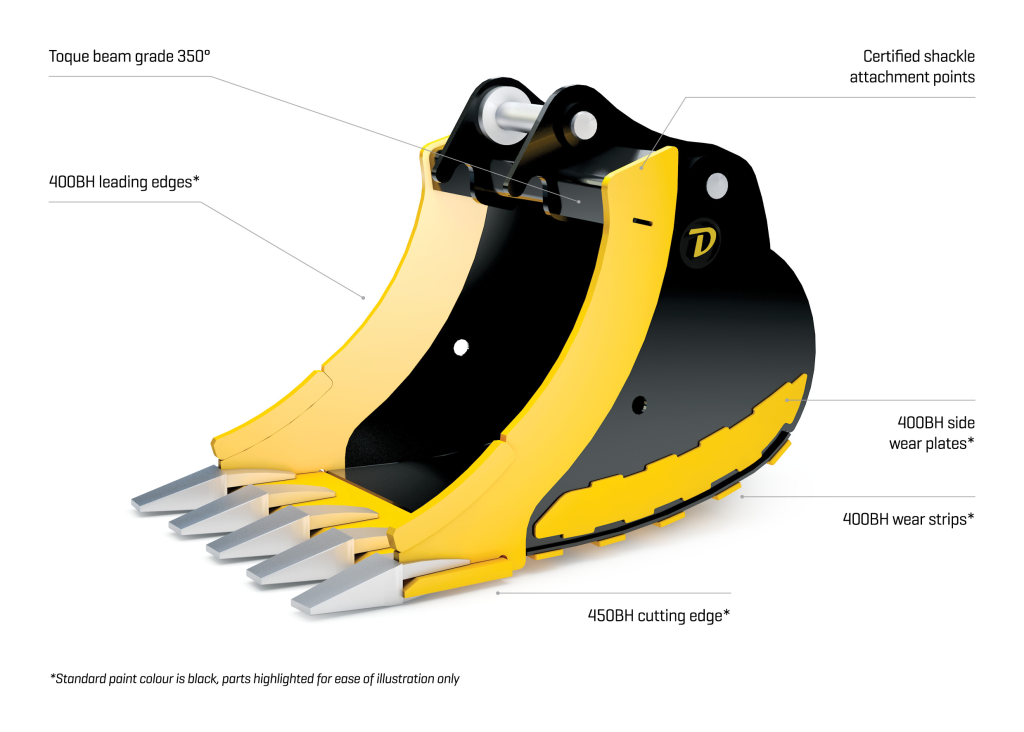

- Rock Buckets – Reinforced with thick, abrasion-resistant steel, rock buckets are built to handle demanding applications like breaking up rocky soil or demolition.

- Landscape Buckets – Designed for precision material handling, landscape buckets have a shallow depth that makes them well-suited for landscaping, gardening, and nursery work.

mini excavator bucket size

Choosing the Right Bucket Size

In addition to bucket type, mini excavator operators must also consider the appropriate bucket size for their machine. Factors like excavator operating weight, engine power, and lift capacity will all influence the optimal bucket size.

As a general guideline, the bucket width should be approximately 50-70% of the mini excavator’s track width. Exceeding this ratio can overload the machine, reducing stability and performance.

It’s also important to match the bucket capacity to the excavator’s lift and breakout force capabilities. Overly large buckets may be too heavy for the mini ex to handle effectively.

For help selecting the right mini excavator bucket, consult with the equipment manufacturer or an attachments specialist. They can provide recommendations based on your specific machine model and the work you need to accomplish.

By equipping your mini excavator with the appropriate bucket, you’ll be able to take on a wider range of jobsite tasks with maximum efficiency and productivity.

What are the different types of digger buckets?

Several bucket types enable an excavator to handle various materials within these applications. While there are also many specialty buckets available, the five most popular buckets include: General-purpose, all-purpose, or digging buckets. Grading, cleaning, or ditching buckets.

What is the difference between a rock bucket and a standard bucket?

Rock buckets can dig into and scoop up hard materials more effectively than standard buckets. They also typically have a more aggressive profile and increased capacity to handle larger volumes of rocky material, ensuring efficient excavation and material handling in rock-heavy environments.

What is the best bucket for digging?

Grading buckets are a popular choice for most work with an excavator. This is because their design offers a smooth and wide cutting edge that work best with all soft materials and soils.

What size bucket for mini excavator?

Excavator bucket size chart

| Machine Size | Recommended Bucket Width in Inches | Recommended Grading Bucket Width in Inches |

|---|---|---|

| < 0.75 ton | 6-24 | 30 |

| 1 ton-1.9 ton | 6-24 | 36 |

| 2 ton-3.5 ton | 9-30 | 36 |

| 4 ton | 12-36 | 36-48 |

How to measure excavator bucket size?

Cross-Sectional Method: This method involves measuring the cross-sectional area of the bucket and multiplying it by the length of the bucket. To do this, take measurements of the bucket’s width and height at the widest point, then multiply these measurements together to get the cross-sectional area.