Key words:Excavator Attachments,Bucket teeth

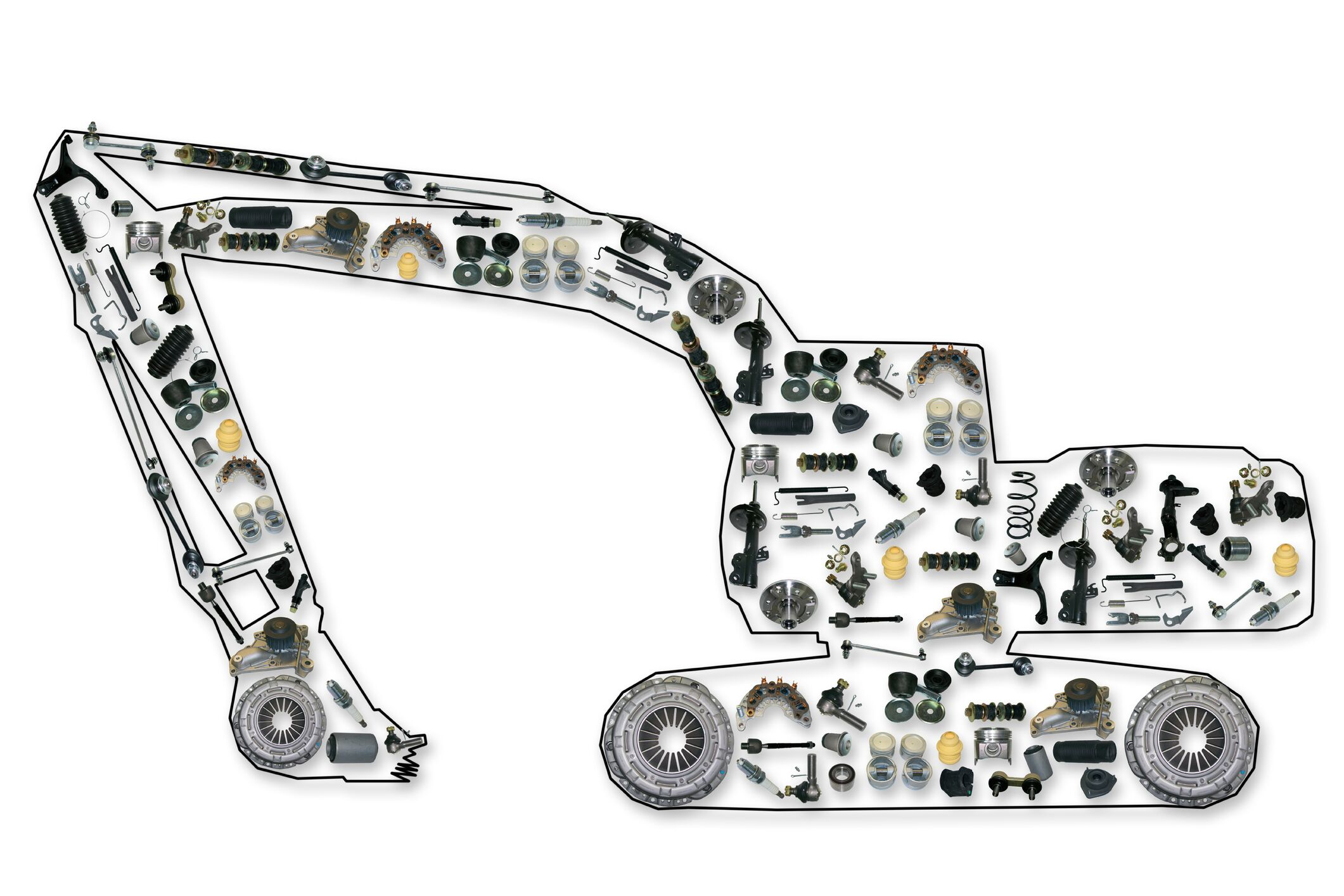

Excavator accessories

Engine Parts:

Piston rings: used to seal the cylinder to prevent gas leakage and ensure normal operation of the engine.

Fuel injector: Injects fuel into the cylinder in the form of mist, mixes with air, and burns to generate power.

Engine cylinder gasket: seals the gap between the cylinder and the cylinder head to prevent gas and coolant leakage.

Crankshaft: Converts the reciprocating motion of the piston into rotational motion and is one of the key components of the engine.

Cylinder head assembly: including cylinder head, valves, valve seats and other components, it is an important part of the engine.

Drivetrain accessories:

Hydraulic pump: Provides hydraulic power to the excavator and drives actuators such as hydraulic cylinders and hydraulic motors.

Hydraulic cylinder: Convert hydraulic energy into mechanical energy to realize various actions of the excavator, such as digging, turning, etc.

Hydraulic motor: drives the excavator to move, rotate, etc.

Travel motor reducer gear box assembly: used for power transmission and deceleration of the traveling system, so that the excavator can travel smoothly.

Chassis and traveling accessories:

Guide wheels, guide wheels, and rollers: used to support and guide the traveling mechanism of the excavator to ensure the stability and accuracy of walking.

Rolling wheels and supporting wheels: bear the weight of the excavator and distribute the weight to the track pads.

Track shoes: in contact with the ground, provide the excavator’s walking ability and protect the chassis from wear.

Electrical control system accessories:

Ignition switch: used to control the starting and stopping of the engine.

Throttle motor:

controls the engine’s throttle and adjusts the engine’s output power.

Electrical sensors: such as water temperature sensor, oil pressure sensor, etc., used to monitor the operating status of the engine and hydraulic system.

It should be noted that due to different excavator models and specifications, the specific models and specifications of the required accessories will also be different. Therefore, when selecting and purchasing Kubota excavator accessories, you need to select and match them according to the specific model and specifications of the excavator.

Bucket teeth

Definition:

Bucket teth refer to the metal parts installed on the edge of the excavator bucket, which are in direct contact with materials (such as soil, rocks, etc.) and excavated.

Function:

Excavation function: Bucket teeth, as the “teeth” of the excavator, can effectively cut and excavate various materials and improve excavation efficiency.

Protect the bucket: During the excavation process, Bucket teeth bear most of the wear, thus protecting the bucket from direct wear and extending the service life of the bucket.

Materials and properties

Material: Bucket teeth are usually made of high-strength, high-wear-resistant materials, such as alloy steel. These materials have good hardness and toughness and can maintain stable performance in harsh working environments.

characteristic:

Wear resistance: Due to direct contact with materials, Bucket teeth need to have good wear resistance to cope with long-term wear.

Impact resistance: During the excavation process, Bucket teeth will be impacted by materials, so they need to have sufficient impact resistance to prevent breakage or damage.

Corrosion resistance: In some special environments, such as humid or dusty environments, Bucket teeth also need to have good corrosion resistance to maintain their performance and life.

Types and Specifications

Type: Bucket teeth come in various types and specifications depending on the excavator model and operating requirements. For example, there are rock-type bucket teeth suitable for digging in hard rock, and there are soil-type bucket teeth suitable for digging in soft soil.

bucket

Structure and composition

Buckets usually consist of bucket body, bucket rod, bucket teeth, bucket ears (or bucket ear plates), side plates, bottom plates and reinforcement ribs. These components are welded or bolted together to form an overall structure that is strong and capable of withstanding excavation forces.

Bucket body: The main part of the bucket, responsible for carrying the excavated material.

Dipper Rod: The component that connects the bucket and the excavator arm. Through the rotation and expansion of the bucket rod, the bucket can excavate at different angles and depths.

Bucket teeth: Sharp parts installed at the front end of the bucket, used to cut into soil, rocks and other materials to improve excavation efficiency.

Dou Er (Dou Er Plate): Located on both sides of the bucket, it is used for connection and support with the excavator arm.

Side plates and bottom plates: constitute the bottom and sides of the bucket, protecting the internal structure and preventing material leakage.

Reinforcement ribs: Reinforcement structures distributed inside and outside the bucket to increase the rigidity and durability of the bucket.

Types and uses

There are many types of buckets, and the choice is based on factors such as the model of the excavator, the working environment, and the type of excavated materials. Common bucket types include standard buckets, rock buckets, reinforced buckets, tilt buckets, etc. Different types of buckets have different structures and characteristics and are suitable for different excavation needs. For example, a standard bucket is suitable for general soil excavation; a rock bucket has a stronger structure and sharper teeth to handle hard rock excavation.