The KMA1265 Case Idler Assembly is a vital component in the undercarriage of various construction and earth-moving machinery. This guide provides an overview of its features, benefits, and importance in maintaining the performance of heavy equipment.

KMA1265 – Case Idler Assembly Compatible Excavator Models

The KMA1265 Case Idler Assembly is an important undercarriage component that is compatible with various excavator models. Below are some common excavator models that this part may fit:

Compatible Excavator Models

- Case 160

- Case 180

- Case 210

- Case 230

- Case CX130

- Case CX160

- Case CX180

- Case CX210

Notes

- Ensure to verify the specific excavator model and compatibility when selecting the KMA1265 Case Idler Assembly.

- It is recommended to refer to the manufacturer’s technical manual for more detailed information and compatibility confirmation.

Key Features

1. Durable Construction

- High-Grade Materials: Built with robust materials that ensure strength and durability under heavy loads and tough working conditions.

- Corrosion Resistance: Coated to resist environmental factors, enhancing longevity and reducing maintenance needs.

2. Precision Engineering

- Exact Fit Design: Specifically designed for compatibility with various machine models, ensuring optimal performance and reliability.

- Tight Manufacturing Tolerances: Engineered to maintain precise alignment, which helps reduce wear on both the idler and the track.

3. Enhanced Load-Bearing Capacity

- Heavy-Duty Support: Capable of supporting significant machine weight, contributing to stability and performance during operation.

- Balanced Weight Distribution: Designed to distribute weight evenly across the undercarriage, minimizing wear and tear.

4. Smooth Operation

- Reduced Friction: Facilitates smooth movement of the track, enhancing the overall efficiency of the machinery.

- Noise Suppression: Engineered for quiet operation, improving the working environment for operators.

5. Maintenance-Friendly

- Easy Lubrication: Features accessible grease fittings that allow for straightforward maintenance and lubrication, promoting reliability.

- Quick Inspection: Designed for easy inspection and monitoring of wear, ensuring timely maintenance actions can be taken.

6. Versatile Application

- Multi-Use Compatibility: Suitable for various models of earth-moving machinery, making it a versatile component for different applications.

- Adaptable Performance: Operates efficiently in diverse environments and conditions, from construction sites to mining operations.

Conclusion

The KMA1265 Case Idler Assembly is crucial for the effective operation of heavy machinery. With its durable construction, precise engineering, and maintenance-friendly design, it plays a significant role in enhancing the performance and lifespan of the equipment.

If you have any additional questions or need further information, feel free to ask!

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.

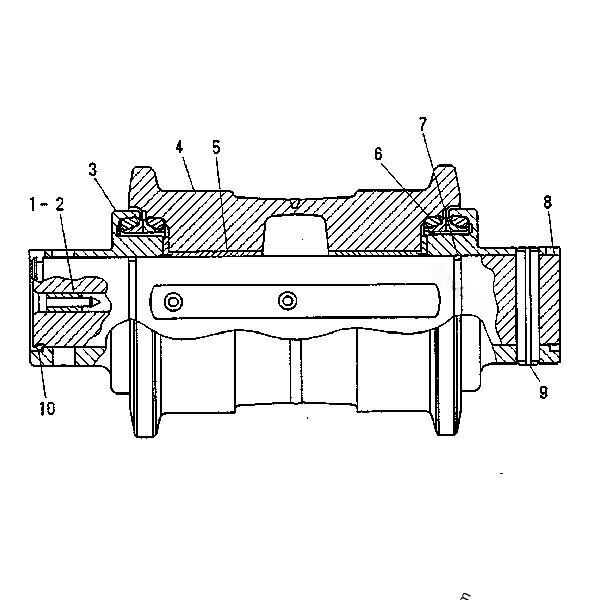

Track roller diagram

| NOTE | No. | PART No. | QTY | PART NAME |

| 1 | 6Y-6201 | 1 | RIXG | |

| 2 | 5G-2247 | 1 | STOPPER | |

| 3 | 6Y-0473 | 1 | PLUG | |

| 4 | 6Y-1054 | 2 | COLLAR | |

| 5 | 6I-9398 | 1 | ROLLER AS | |

| 6 | 6I-9399 | 2 | BEARING | |

| 7 | 1H-8720 | 2 | SEAL | |

| 8 | 6I-9397 | 1 | SHAFT | |

| 9 | 9W-2204 | 1 | PIN | |

| 10 | 9W-7225 | 2 | SEAL GP |