Everything You Need to Know About the 1028151 Idler Group for Caterpillar 320

The 1028151 Idler Group is a critical component used in Caterpillar 320 series excavators. This guide provides detailed information on its specifications, features, applications, and maintenance tips.

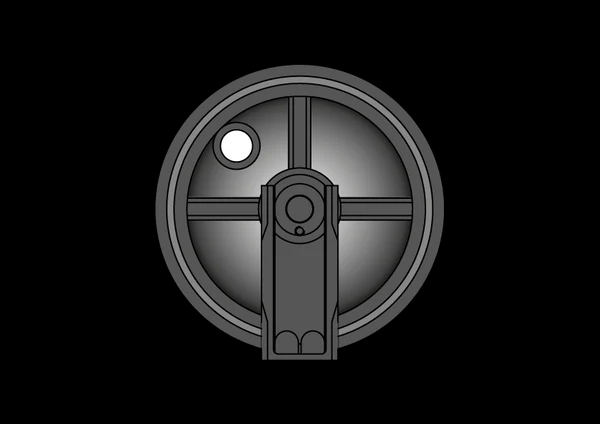

1. Overview of the 1028151 Idler Group

- Purpose: The idler group serves to guide the track system of the excavator, maintaining proper tension and alignment of the tracks during operation.

- Applications: Specifically designed for use in Caterpillar 320 series excavators.

2. Specifications

| Feature | Details |

|---|---|

| Part Number | 1028151 |

| Manufacturer | Caterpillar |

| Type | Idler Group |

| Compatibility | Caterpillar 320 series excavators |

| Material | High-strength steel for durability |

| Weight | Varies based on configuration |

3. Key Features

- Durability: Built to withstand the rigors of heavy-duty applications, ensuring a long lifespan.

- Design: Engineered to provide optimal performance in guiding and maintaining track tension.

- Sealed Bearings: Many idler groups feature sealed bearings to protect against dirt and debris, reducing maintenance frequency.

- Easy Installation: Designed for straightforward installation, minimizing downtime during replacement.

4. Applications

- Construction: Used in excavators for various construction tasks, including digging, lifting, and moving materials.

- Landscaping: Assists in landscaping and earth-moving activities that require precision and stability.

- Demolition: Essential for demolition work where heavy machinery is needed to break down structures efficiently.

- Mining: Commonly utilized in mining operations for excavation and material handling.

5. Maintenance Tips

Regular Inspections

- Inspect the idler group regularly for signs of wear, such as cracks or excessive rust, to prevent operational issues.

Lubrication

- Ensure proper lubrication of the idler bearings to minimize friction and wear. Use the recommended grease type as specified by Caterpillar.

Check Alignment

- Regularly verify the alignment of the idler group with the tracks to prevent uneven wear and extend the lifespan of both the idler and the tracks.

Monitor Track Tension

- Maintain proper track tension to ensure the idler operates efficiently and does not experience excessive wear or damage.

Replace as Needed

- If you notice significant wear or damage, replace the idler group promptly to maintain the machine’s performance and safety.

6.Benefits

1. Enhanced Durability

- Wear Resistance: Built to resist wear and tear, extending the lifespan of the idler and reducing the need for frequent replacements.

- Impact Strength: Designed to absorb shocks and impacts, ensuring reliability in tough environments.

2. Improved Performance

- Smooth Operation: Contributes to the overall efficiency of the excavator by facilitating smooth track movement.

- Stability: Enhances stability during operation, allowing for better control and maneuverability.

3. Cost-Effectiveness

- Reduced Maintenance Costs: A durable idler group can lead to fewer repairs and lower overall maintenance expenses.

- Longer Operational Life: Investing in a high-quality idler can significantly extend the life of your machinery.

4. Ease of Installation

- Quick Replacement: Designed for straightforward installation, allowing for efficient maintenance and reduced downtime.

- Compatibility: Specifically designed for a range of Caterpillar models, simplifying the replacement process.

Conclusion

The 1028151 Idler Group is an essential component that contributes significantly to the performance and longevity of Caterpillar 320 series excavators. Understanding its specifications, features, and maintenance requirements is crucial for operators and owners to ensure optimal functionality. If you have any further questions or need assistance regarding this idler group or related components, feel free to reach out!

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.