Comprehensive Guide to 2270-1052 Daewoo Idler Assembly

The 2270-1052 Daewoo Idler Assembly is an essential component in the undercarriage of Daewoo heavy machinery. This guide includes detailed information on its specifications, benefits, applications, and maintenance practices.

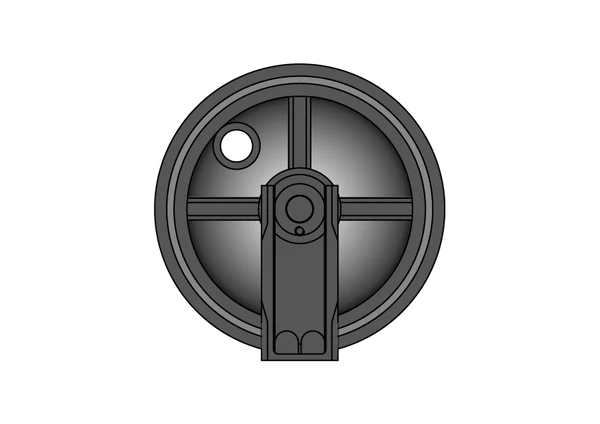

1. Overview of 2270-1052 Daewoo Idler Assembly

- Purpose: The idler assembly supports and guides the track system, maintaining proper tension and ensuring efficient operation of machinery.

- Applications: Commonly utilized in various Daewoo models, particularly in construction and excavation equipment.

2. Specifications

| Feature | Details |

|---|---|

| Part Number | 2270-1052 |

| Manufacturer | Daewoo |

| Type | Idler Assembly |

| Material | High-strength steel for durability |

| Compatibility | Specific Daewoo models (e.g., DH series) |

3. Key Benefits

- Durability: Built from high-strength materials designed to withstand heavy loads and harsh conditions.

- Smooth Operation: Ensures smooth movement of the tracks, contributing to the overall performance of the machinery.

- Reduced Maintenance: Features that simplify maintenance, such as sealed bearings, help prevent debris ingress and reduce wear.

- Cost-Effectiveness: Long lifespan and lower replacement frequency lead to reduced operational costs.

- Safety: Maintains proper track tension, minimizing the risk of equipment failure and enhancing worksite safety.

4. Applications

- Construction: Utilized in excavators for tasks like digging, lifting, and transporting materials.

- Mining: Essential for heavy machinery in mining operations where durability is crucial.

- Demolition: Commonly found in demolition equipment, aiding in efficient material breakdown.

- Landscaping: Used in earth-moving and landscaping projects for stability and precision.

5. Maintenance Tips

Regular Inspections

- Conduct periodic checks for signs of wear, such as cracks or corrosion, to identify potential issues early.

Lubrication

- Ensure that the bearings in the idler assembly are properly lubricated to minimize wear and prolong life.

Track Tension Monitoring

- Regularly monitor and adjust track tension to ensure optimal performance and prevent uneven wear.

Alignment Checks

- Verify the alignment of the idler with the tracks to ensure smooth movement and reduce stress on the machinery.

Prompt Replacement

- If significant wear or damage is observed, replace the idler assembly promptly to maintain safe and effective operation.

6. Conclusion

The 2270-1052 Daewoo Idler Assembly is a vital component that significantly affects the performance and reliability of Daewoo heavy machinery. Understanding its specifications, benefits, and maintenance requirements is essential for operators and equipment owners to ensure optimal functionality and longevity. If you have any further questions or need additional assistance regarding this idler assembly or related components, feel free to ask!

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.