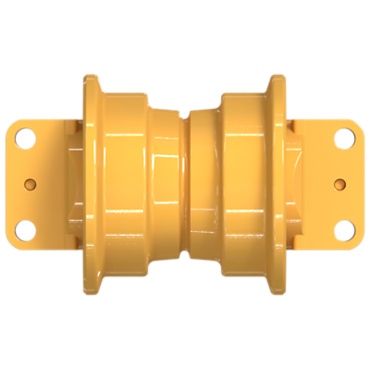

127-3806 Single flange roller assembly

The 127-3806 Single Flange Roller Assembly is an important component used in the undercarriage systems of heavy machinery, particularly in Caterpillar equipment. This assembly plays a crucial role in enhancing the performance and reliability of machinery operating in various conditions.

Key Features of 127-3806 Single Flange Roller Assembly

- Single Flange Design: Designed with a single flange, providing effective support and stability for the tracks.

- Durable Construction: Made from high-quality materials to withstand heavy loads and harsh working environments.

- Compatibility: Specifically engineered for use in Caterpillar machinery, ensuring a perfect fit and optimal performance.

Functionality of the 127-3806 Roller Assembly

The roller assembly serves several essential purposes:

- Track Support: Provides support for the tracks, allowing for smoother movement across different terrains.

- Weight Distribution: Aids in evenly distributing the weight of the equipment, which reduces wear on other undercarriage components.

- Enhanced Stability: Contributes to the overall stability of the machinery during operation, improving safety and efficiency.

Advantages of Using the 127-3806 Roller Assembly

- Increased Performance: Enhances the performance of heavy machinery by ensuring proper track alignment and support.

- Longevity: Built to endure tough operating conditions, leading to fewer replacements and lower maintenance costs.

- Cost-Effective: Reduces the need for frequent repairs and maintenance, making it a wise investment for operators.

Maintenance Recommendations

To maximize the performance and lifespan of the 127-3806 Single Flange Roller Assembly, consider the following maintenance practices:

- Regular Inspections: Conduct routine checks for signs of wear, damage, or misalignment.

- Adequate Lubrication: Ensure the roller assembly is properly lubricated to minimize friction and heat during operation.

- Track Condition Monitoring: Keep an eye on the condition of the tracks to prevent excessive wear on the roller assembly.

- Debris Clearance: Regularly clear debris around the assembly to prevent buildup that could impede performance.

Functionality of the 127-3806 Track Roller

The bottom/track roller plays several important roles:

- Support for Tracks: Provides critical support to the tracks, allowing for efficient movement of the machinery.

- Weight Distribution: Aids in evenly distributing the weight of the machine, reducing stress on other undercarriage components.

- Friction Reduction: Minimizes friction between the track and ground, improving fuel efficiency and overall performance.

Advantages of Using the 127-3806 Track Roller

- Enhanced Performance: Improves the overall performance of Caterpillar machinery by maintaining proper track alignment.

- Durability: Designed to endure challenging environments, leading to fewer replacements and lower maintenance costs.

- Cost Efficiency: Reduces downtime and maintenance needs, making it a valuable investment for equipment operators.

Maintenance Recommendations

To ensure optimal performance and longevity of the 127-3806 CAT Bottom / Track Roller, consider the following maintenance practices:

Debris Management: Regularly clean the area around the roller to prevent debris accumulation that could affect performance.

Frequent Inspections: Regularly check for signs of wear, damage, or misalignment.

Proper Lubrication: Maintain adequate lubrication to reduce friction and wear on the roller.

Monitor Track Condition: Keep an eye on the tracks to prevent excessive wear on the roller.