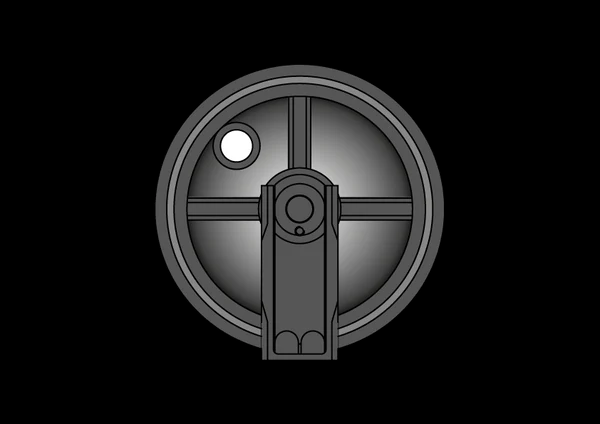

It seems that I couldn’t find specific information regarding the 200102-00020 Idler. However, I can provide some general insights about idlers used in heavy machinery, which may help you understand their importance and functionality.

Overview of Idlers in Heavy Machinery

Idlers are crucial components in the undercarriage systems of tracked vehicles, such as excavators and bulldozers. They serve several important functions:

- Support and Guidance: Idlers help support the track system and guide the movement of the tracks, ensuring smooth operation.

- Track Tension Maintenance: They maintain proper tension in the tracks, which is essential for efficient performance and to prevent track slippage.

- Durability: Idlers are typically made from high-strength materials to withstand heavy loads and harsh working conditions.

- Reduced Vibration: A well-functioning idler helps to dampen vibrations, leading to a more stable operation and improved operator comfort.

- Cost-Effectiveness: Durable idlers reduce the need for frequent replacements, which can lower overall maintenance costs.

Maintenance Tips for Idlers

To ensure the longevity and performance of idlers, consider the following maintenance practices:

- Regular Inspections: Check for signs of wear, such as cracks or rust, to catch potential issues early.

- Lubrication: Ensure that bearings are properly lubricated to minimize wear.

- Track Tension Monitoring: Regularly monitor and adjust track tension for optimal performance.

- Alignment Checks: Verify the alignment of the idler with the tracks to reduce stress on the machinery.

If you have any specific questions or need further assistance regarding the 200102-00020 Idler, feel free to ask!

Benefits

- Enhanced Performance

- Improves the efficiency and effectiveness of tracked machinery, leading to increased productivity.

- Cost Efficiency

- Lower Maintenance Costs: By ensuring proper operation, it reduces potential damage to the track system.

- Longer Lifespan: A durable idler can extend the life of the overall track assembly.

- Safety

- Promotes stable operation, minimizing the risk of accidents and enhancing safety for operators.

- Easy Installation

- Designed for straightforward installation, allowing for quick replacements and minimal downtime.

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.