Everything You Need to Know About the 270-00015 Idler

The 270-00015 idler is a crucial component used in various heavy machinery, particularly in track-type vehicles. This guide will cover its specifications, features, applications, maintenance tips, and troubleshooting common issues.

1. Overview of the 270-00015 Idler

The 270-00015 idler serves the purpose of supporting the track system and maintaining proper tension in the tracks. Its robust design ensures stability and smooth operation of the machinery.

2. Key Specifications

| Feature | Details |

|---|---|

| Part Number | 270-00015 |

| Material | High-Strength Steel |

| Weight | Varies by Manufacturer |

| Dimensions | Model-Specific |

| Compatibility | Multiple Heavy Machinery Models |

3. Key Features

Durability

- Wear Resistance: Made from high-quality materials designed to withstand harsh conditions.

- Long Lifespan: Built to provide extended service life under demanding operational conditions.

Performance

- Optimal Load Distribution: Ensures even distribution of weight across the track system, enhancing stability.

- Improved Tracking: Helps maintain proper tension in the tracks for better performance.

Ease of Installation

- User-Friendly Design: Easy to install, allowing for quick replacements and minimal equipment downtime.

- Versatile Compatibility: Fits various heavy machinery models, making it adaptable to different equipment types.

Low Maintenance Requirements

- Minimal Upkeep: Requires little maintenance, enabling operators to concentrate on productivity.

- Routine Inspections: Regular checks help ensure longevity and optimal performance.

4. Applications

The 270-00015 idler is commonly utilized in various applications, including:

- Excavation: Provides support and stability for excavators during digging operations.

- Construction: Essential for bulldozers and other earth-moving machinery.

- Agriculture: Used in agricultural machinery for efficient land management.

5. Maintenance Tips

To ensure the longevity and efficiency of the 270-00015 idler, consider the following Everything You Need to Know About the 270-00015 Idler

The 270-00015 idler is a critical component used in the track systems of various heavy machinery, particularly in construction and mining equipment. This guide provides detailed information about its specifications, features, applications, maintenance, and troubleshooting tips.

6. Troubleshooting Common Issues

1. Uneven Wear

- Cause: Misalignment or incorrect tension in the track system.

- Solution: Check for proper alignment and adjust the tension as necessary.

2. Excessive Noise

- Cause: Lack of lubrication or damaged idlers.

- Solution: Inspect for damage and ensure that the idlers are properly lubricated.

3. Reduced Performance

- Cause: Debris buildup or wear in the track system.

- Solution: Clean the track system thoroughly and inspect for any signs of damageation**: Ensure that all moving parts are adequately lubricated to minimize friction and wear.

7. Conclusion

The 270-00015 idler is a vital component in ensuring the stability and efficiency of heavy machinery. Understanding its specifications, features, applications, and maintenance requirements is essential for optimal performance. If you have any further questions or need additional information, feel free to ask!

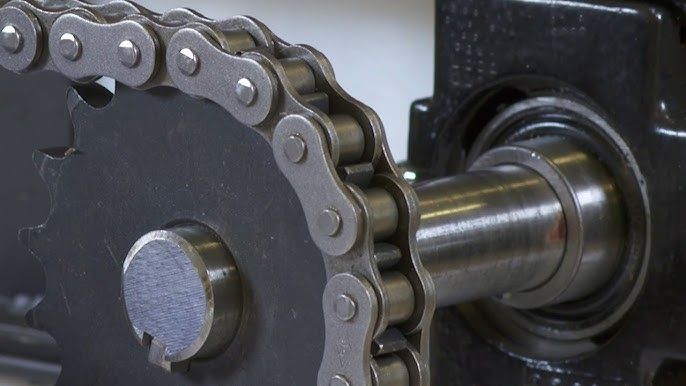

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.