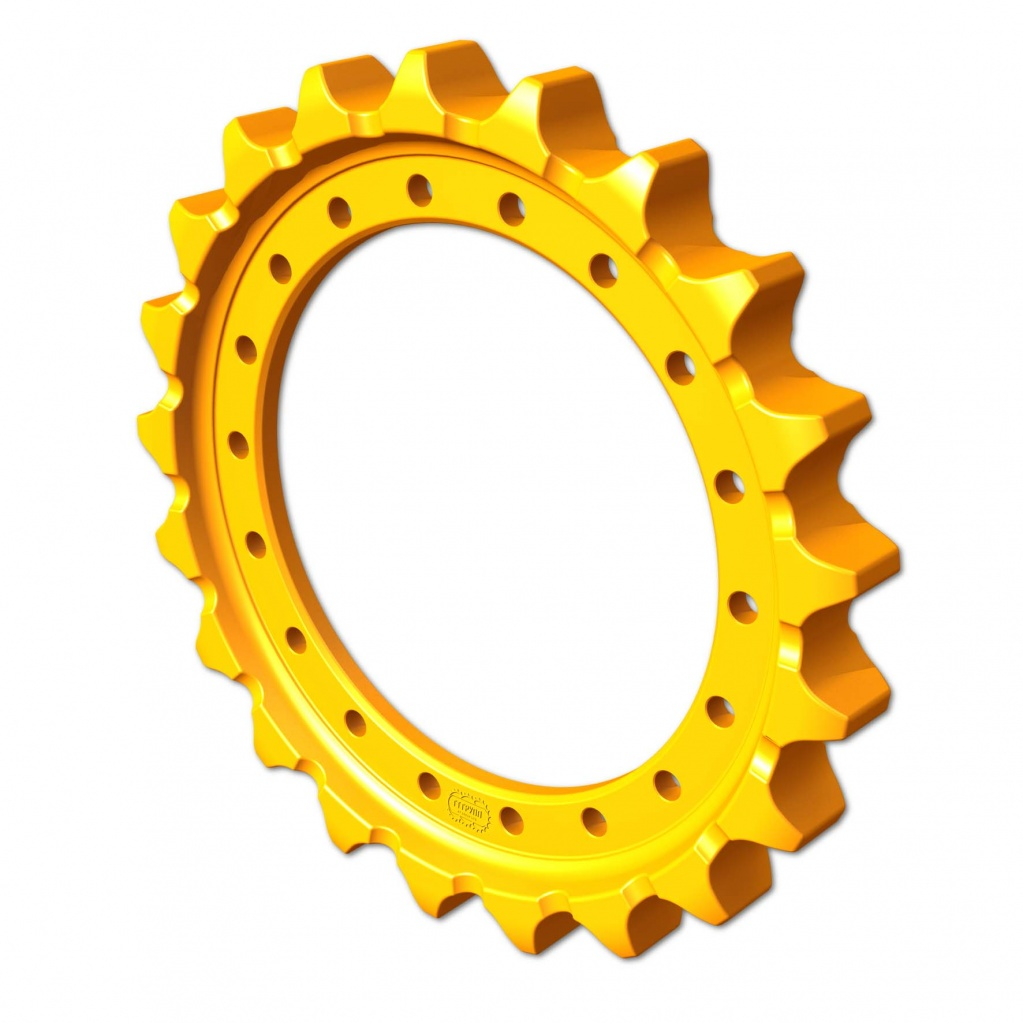

The S02716-00100 Sprocket: A Comprehensive Overview

The S02716-00100 sprocket is an essential component used in various types of heavy machinery, particularly in tracked vehicles. This guide provides detailed information about its features, benefits, applications, installation, and maintenance.

1. Key Features of the S02716-00100 Sprocket

Specifications

- Material: Typically made from high-strength steel or alloy for enhanced durability.

- Tooth Design: Precision-engineered teeth for optimal engagement with tracks, ensuring efficient power transfer.

- Compatibility: Designed to fit specific models of excavators, bulldozers, and other tracked equipment.

Dimensions

- Diameter: Varies based on specific applications; ensure to check the exact measurements.

- Number of Teeth: Configured with a specific number of teeth to match the machinery’s operational requirements.

2. Benefits of Using the S02716-00100 Sprocket

- Improved Performance: Facilitates smoother operation and effective power transfer, enhancing overall machinery efficiency.

- Durability: Built to endure heavy loads and harsh environments, leading to fewer replacements and repairs.

- Cost-Effectiveness: Reduces long-term costs due to lower maintenance needs and extended lifespan.

- Enhanced Traction: Provides reliable engagement with tracks, improving stability and control during operation.

3. Applications of the S02716-00100 Sprocket

The S02716-00100 sprocket is commonly found in:

- Excavators: For digging, lifting, and moving materials effectively.

- Bulldozers: Enhancing pushing and grading capabilities.

- Other Heavy Machinery: Any tracked equipment requiring dependable power transmission.

4. Installation Process

Tools Required

- Wrenches

- Torque wrench

- Lifting equipment (if necessary)

Installation Steps

- Remove the Old Sprocket: Detach the existing sprocket using appropriate tools.

- Clean the Mounting Area: Ensure the area is free of debris and dirt for a secure fit.

- Position the New Sprocket: Align the S02716-00100 sprocket with the mounting holes.

- Secure the Sprocket: Attach using bolts and fasteners, tightening to the manufacturer’s specifications.

- Check Alignment: Ensure it is properly aligned with the track for optimal performance.

5. Maintenance Guidelines

Routine Inspections

- Visual Checks: Regularly inspect for signs of wear, damage, or misalignment.

- Lubrication: Follow the manufacturer’s recommendations for lubrication intervals to maintain smooth operation.

Cleaning Procedures

- Debris Removal: Keep the sprocket clean from mud and dirt to prevent wear.

- Washing: Use mild detergents and a brush for thorough cleaning when necessary.

Adjustments

- Track Tension: Regularly check and adjust track tension to minimize strain on the sprocket.

6. Troubleshooting Common Issues

Common Symptoms and Solutions

- Uneven Wear:

- Cause: May result from improper installation or misalignment.

- Solution: Reassess the installation and make necessary adjustments.

- Excessive Noise:

- Cause: Could indicate insufficient lubrication or damaged sprocket teeth.

- Solution: Lubricate as needed and inspect for any damage.

- Frequent Failures:

- Cause: Likely due to poor maintenance or incorrect component use.

- Solution: Review maintenance practices and ensure proper part compatibility.

7. Conclusion

The S02716-00100 sprocket plays a crucial role in the performance and reliability of heavy machinery. By understanding its features, benefits, and maintenance practices, you can significantly enhance the effectiveness of your equipment. If you have any further questions or need assistance, feel free to reach out!

How to Install an 81N6-10012 Sprocket

Installing the S02716-00100 sprocket correctly is essential for the performance of your machinery. Follow these steps to ensure a successful installation.

Tools and Materials Needed

- Basic Tools:

- Socket set

- Wrenches

- Torque wrench

- Screwdrivers

- Safety Gear:

- Gloves

- Safety goggles

- Replacement Parts:

- S02716-00100 sprocket

- Any necessary gaskets or seals

Installation Steps

1. Safety Preparations

- Turn Off the Equipment: Ensure the machinery is turned off and parked on a stable surface.

- Use Wheel Chocks: Secure the equipment with wheel chocks to prevent movement during installation.

2. Remove the Old Sprocket

- Access the Sprocket: Depending on your machinery, you may need to remove covers or guards to access the sprocket.

- Loosen Fasteners: Use the appropriate socket or wrench to loosen and remove the bolts securing the old sprocket.

- Remove the Old Sprocket: Carefully pull the old sprocket off the shaft. If it’s stuck, gently tap it with a rubber mallet to free it.

3. Prepare the New Sprocket

- Inspect the New Sprocket: Check the S02716-00100 sprocket for any damage or defects before installation.

- Clean the Shaft: Wipe down the shaft where the sprocket will be mounted to ensure a clean fit.

4. Install the New Sprocket

- Position the Sprocket: Align the new sprocket with the shaft, ensuring that any keyways or alignment marks are correctly matched.

- Secure the Sprocket: Slide the sprocket onto the shaft until it is fully seated.

5. Fasten the Sprocket

- Install Bolts: Insert and hand-tighten the bolts that secure the sprocket to the shaft.

- Torque Specifications: Use a torque wrench to tighten the bolts to the manufacturer’s specified torque settings. This ensures a secure fit without over-torquing.

6. Reassemble Any Removed Components

- Replace Covers or Guards: If you removed any components to access the sprocket, reattach them securely.

- Double-Check Fasteners: Ensure all fasteners are tightened appropriately.

7. Final Checks

- Inspect Installation: Look over the installation to ensure everything is aligned and secured correctly.

- Run a Test: Start the machinery and run it at low speed to verify that the sprocket operates smoothly without unusual noises or vibrations.

Conclusion

By following these steps, you can successfully install the S02716-00100 sprocket and ensure optimal performance of your machinery. If you have any further questions or need assistance, feel free to ask!

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.