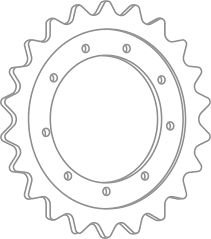

KLA0158 Sprocket: A Detailed Overview

The KLA0158 sprocket is an important component utilized in various machinery, particularly in construction and agricultural equipment. This guide provides an overview of its specifications, applications, features, and maintenance advice.

1. Specifications of KLA0158 Sprocket

| Specification | Details |

|---|---|

| Part Number | KLA0158 |

| Type | Sprocket |

| Material | High-strength steel |

| Teeth Count | Typically 12-16 teeth |

| Outer Diameter | Approximately 250-300 mm |

| Inner Diameter | Compatible with standard shaft sizes |

| Weight | Approximately 4-6 kg |

2. Applications of KLA0158 Sprocket

- Excavators: Used in the drive system for tracks and rotation.

- Bulldozers: Essential for track movement and power distribution.

- Agricultural Equipment: Found in tractors, tillers, and harvesters.

- Material Handling Equipment: Utilized in conveyor systems and other machinery where power transfer is essential.

3. Features of the KLA0158 Sprocket

- Durability: Engineered to withstand heavy loads and tough working conditions.

- Precision Engineering: Manufactured to meet strict dimensional tolerances for optimal performance.

- Easy Installation: Designed for straightforward installation and replacement, minimizing downtime.

4. Maintenance Tips for Sprockets

- Regular Inspections: Conduct routine checks for wear and damage to ensure safe and efficient operation.

- Lubrication: Apply appropriate lubricants to reduce friction and extend the lifespan of the sprocket.

- Alignment Checks: Ensure proper alignment with other components to prevent excessive wear.

- Replacement: Replace sprockets that show significant wear, cracks, or other damage promptly to maintain optimal machine performance.

Key Features

- Robust Design: Made from high-quality materials to endure heavy loads and harsh conditions.

- Precision Fit: Engineered for compatibility with various track systems, ensuring reliable performance.

- Standardized Dimensions: Typically conforms to industry standards, making it suitable for a range of machinery.

Applications

- Construction Equipment: Widely used in excavators, bulldozers, and other tracked machinery for efficient operation.

- Agricultural Machinery: Common in tractors and other farming equipment, enhancing mobility on uneven terrain.

- Mining Operations: Essential for tracked vehicles in mining, providing stability and durability.

Maintenance Tips

- Regular Inspections: Frequently check for signs of wear, cracks, or other damage. Replace if necessary.

- Proper Lubrication: Ensure the sprocket is adequately lubricated to minimize friction and extend its life.

- Alignment Checks: Verify alignment with the track to prevent uneven wear and improve efficiency.

- Debris Management: Keep the sprocket area clean from dirt and debris to maintain optimal performance.

5. Conclusion

The KLA0158 sprocket plays a vital role in the functionality of various machinery used in construction and agriculture. Understanding its specifications and applications can facilitate effective maintenance and improve the longevity of equipment. If you have any further questions or need additional information about the KLA0158 sprocket, feel free to ask!

Undercarriage parts

The excavator undercarriage is the foundation that supports the entire machine, consisting of critical components such as track shoes, rollers, idlers, and sprockets that work together to provide traction, stability, and mobility. These durable parts are engineered to withstand the intense stresses and harsh operating conditions encountered during construction, demolition, and earthmoving tasks, and their proper maintenance and replacement are crucial for ensuring the excavator’s long-term performance and reliability. The undercarriage plays a vital role in the excavator’s overall capabilities, enabling it to traverse a wide range of terrains and job site conditions with confidence and efficiency.